A Professional Guide To Use Magnetic Drilling Machines

This article is the extended version of, how to use a magnetic drilling machine?

Professional drilling with the following instructions will result in perfectly finished holes, in less time and with more service life of both the annular cutter as well as the magnetic drilling machine.

The Below Article Gives Complete Information About How To Use Magnetic Drill Press (Magnetic Drilling Machine), How To Use Annular Cutters, Professional Tips On Better Service Life Of Annular Cutter And Magnetic Drill Press, Fundamental Safety Instruction For Using Magnetic Drilling Machine, Handling Of The Magnetic Drilling Machine, Instructions For Drilling Horizontally or Overhead, Instructions About Material To Be Drilled, Cleaning The Magnetic Drilling Machine After Use, etc.

A. Selection Of Magnetic Drilling Machine:

There are various types of magnetic drilling machine available in the market, chose the best suitable magnetic drilling machine or magnetic drill press for your purpose. The types of magnetic drilling machines are details in our previous article: Types Of Magnetic Drilling Machine

B. Selection Of Annular Cutters:

Mainly annular cutters are of two types High-Speed Steel (HSS) Annular Cutters and Tungsten Carbide Tip (TCT) Annular Cutters. We recommend the use of HSS Annular Cutters for your regular drilling jobs because HSS annular cutters are cheaper in price, can be re-sharpen, need less RPM which reduces the load on your magnetic drilling machine and increases the machines’ service life.

The TCT Annular Cutters must only be used while drilling more than 40 mm (1 9/16 inches) diameter because above this diameters the TTCT Annular Cutters get cheaper in price and are more faster to drill.

The TCT Annular Cutters should also be used while drilling very hard material like for drilling stainless steel, drilling HARDOX, drilling INOX, etc. For normal metal which is not very hard, HSS Annular Cutters are the best.

C. Below Are The Instructions On How To Use A Magnetic Drill Press And An Annular Cutter Professionally:

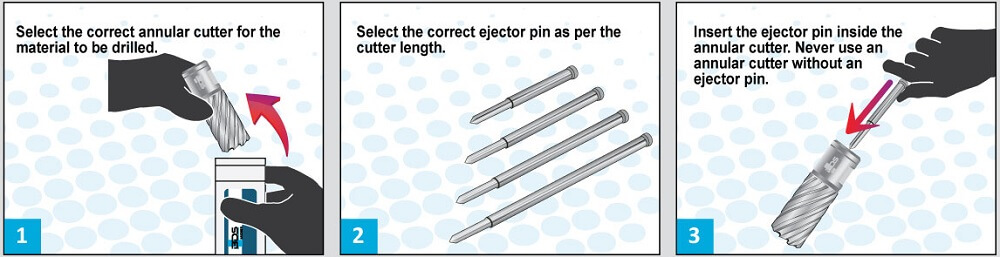

- Select the correct annular cutter for the material to be drilled.

- Select the correct ejector pin for the cutter length.

- Insert the ejector pin inside the annular cutter. Never use an annular cutter without an ejector pin.

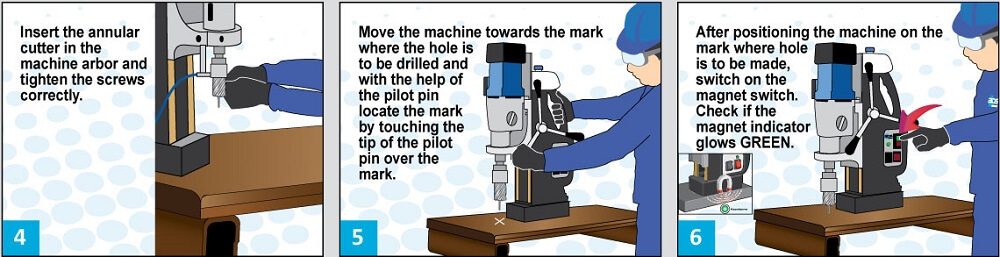

- Insert the annular cutter in the machine arbor and tighten the screws correctly.

- Move the machine towards the mark where the hole is to be drilled and with the help of the pilot pin locate the mark by touching the tip of the pilot pin tip over the mark.

- After positioning the machine on the mark where the hole is to be made, switch on the magnet switch of the magnetic drilling machine. Check if the magnet indicator glows GREEN. If, the magnet indicators glows RED that means the magnet does not have enough material below for a perfect adhesion. In an ideal condition, the thickness of the material to be drilled must be minimum 8 mm (5/16 inches)

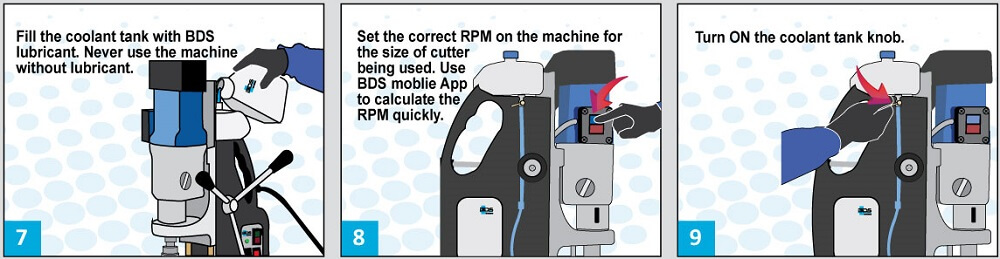

- Fill the coolant tank with lubricant. Never use the machine without lubricant. for HSS annular cutters use cutting oil and for TCT annular cutters use water soluble coolant.

- Set the correct RPM on the machine for the size of the cutter being used. The formula for calculating RPM (n) is n = (v X 1000) / ( d X 3.14). Where v is the cutting speed of the annular cutter and d is the diameter of the annular cutter. You can also use our website to automatically calculate the RPM. Please click on this link: https://bds-machines.eu/rpm-calculator/

- Turn ON the coolant tank knob of the magnetic drill press.

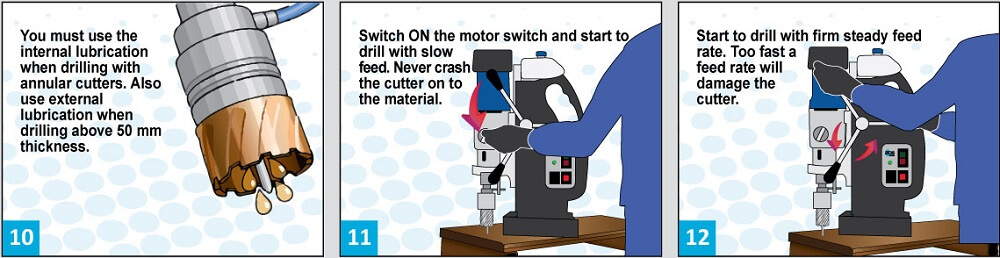

10. You must use the internal lubrication when drilling with annular cutters and also use external lubrication when drilling above 50 mm (1 15/16 inches) thickness.

11. Switch ON the motor switch of the magnetic drill press and start to drill with slow feed. Do not crash the cutter on to the material.

12. Start to drill with a firm steady feed rate. Too slow or too fast feed rate will damage the annular cutter.

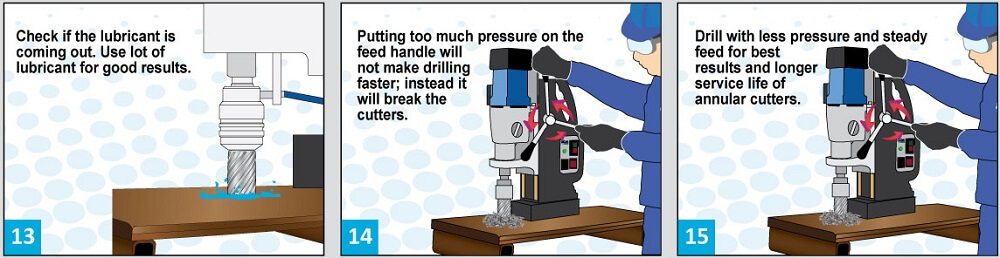

13. Check if the lubricant is coming out. Use a lot of lubricant for good results.

14. Putting too much pressure on the feed handle will not make drilling faster; instead, it will break the annular cutters.

15. Drill with less pressure and steady feed for best results and longer service life of annular cutters.

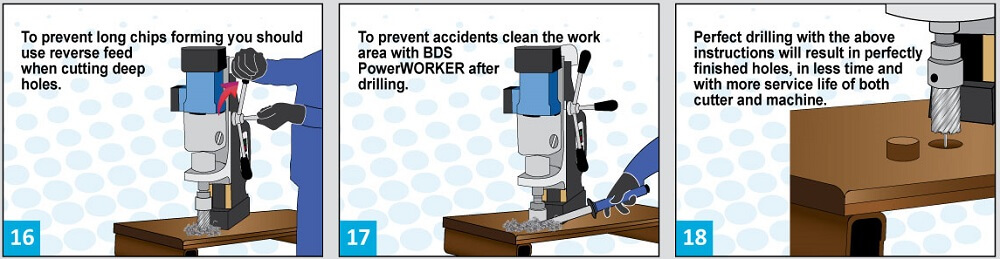

16. To prevent long chips forming you should use reverse feed when cutting deep holes.

17. To prevent accidents clean the work area with BDS PowerWORKER or appropriate cleaning tool after drilling.

18. Perfect drilling with the above instructions will result in perfectly finished holes, in less time and with more service life of both cutter and machine.

D. Video About How To Use Magnetic Drill Press and Annular Cutters:

E. Poster How To Use Magnetic Drill Press and Annular Cutters:

Please Click On The Poster To Download!

F. Fundamental Safety Instruction For Using Magnetic Drilling Machine:

■ Do not use the magnetic drilling machine (magnetic drill press) in potentially flammable or explosive environments.

■ Persons, who are unable to safely operate the magnetic drilling machine (magnetic drill press) due to their physical, mental or motor abilities, my only use the magnetic drilling machine (magnetic drill press) under the supervision or instruction of a person responsible.

■ Persons with heart pacemakers or other medical implants must not use this magnetic drilling machine (magnetic drill press).

■ Children are not permitted to use the magnetic drilling machine (magnetic drill press).

■ Inspect the magnetic drilling machine (magnetic drill press) for visible signs of damage before use. Do not operate a damaged magnetic drilling machine (magnetic drill press).

■ Before beginning work, check the condition of the safety chain and the function of the switches on the magnetic drilling machine (magnetic drill press).

■ Repairs to the connecting cable may only be performed by a qualified electrician.

■ Repairs to the magnetic drilling machine (magnetic drill press) may only be performed by an authorised specialist workshop or factory customer service.

Unqualified repairs can lead to considerable danger for the user.

■ Repairs to the magnetic drilling machine (magnetic drill press) during the guarantee period may only be performed by a customer service authorised by the manufacturer, otherwise, the guarantee is invalid.

■ Defective parts may only be replaced with original spare parts. Only these parts ensure that the safety requirements are met.

■ Do not leave the magnetic drilling machine (magnetic drill press) unsupervised during operation.

■ Store the magnetic drilling machine (magnetic drill press) in a dry, temperate location out of the reach of children.

■ Do not allow the magnetic drilling machine (magnetic drill press) to stand outside and do not expose to moisture.

■ Make sure that your work area is sufficiently lit (>300 Lux).

■ Do not use low-power magnetic drilling machine (magnetic drill press)s for heavy working.

■ Keep the magnetic drilling machine (magnetic drill press) clean, dry and free of oil and grease.

■ Follow the instructions on lubricating and cooling the tool.

G. Danger Of Electric Shock (Current):

Contact with live wires or components can lead to serious injury or even death!

Observe the following safety precautions to avoid any danger from electric current:

► Do not open the housing of the magnetic drilling machine (magnetic drill press). Risk of electric shock from touching live connections.

► Never immerse the magnetic drilling machine (magnetic drill press) or mains plug in water or other liquids.

► Only use extension cables or cable drums with a cable cross-section of at least 1.5 mm².

► Only use extension cables that are approved for the location of use.

► Check the condition of the extension cable regularly and replace if damaged.

► Avoid bodily contact with grounded parts (e.g., pipes, radiators, steel girders) to reduce the risk of electric shock in the event of a defect.

► When using the magnetic drilling machine (magnetic drill press) outside or in a humid environment, an RCD (residual circuit device) must be used.

H. Handling Of The Magnetic Drilling Machine:

Improper handling of the magnetic drilling machine (magnetic drill press) increases the risk of injury!

Pay attention to the following safety instructions in order not to injure others or yourself:

► Operate the magnetic drilling machine (magnetic drill press) only with the protective equipment specified in these instructions.

► Do not wear protective gloves when the magnetic drilling machine (magnetic drill press) is running. A glove can be caught by the drilling magnetic drilling machine (magnetic drill press) and torn off the hand. Risk of losing one or more fingers.

► Remove loose jewelry before beginning work.

► Wear a hair net if you have long hair.

► Always switch off the magnetic drilling machine (magnetic drill press) before changing tools, performing maintenance or cleaning. Wait until the magnetic drilling machine (magnetic drill press) has come to a complete standstill.

► Always remove the plug from the mains socket before changing tools, cleaning or performing maintenance work in order to avoid unintentional starting of the magnetic drilling machine (magnetic drill press).

► Do not put your hand into the machine while it is in operation. Remove swarf only when the magnetic drilling machine (magnetic drill press) is at a standstill. Wear protective gloves when removing swarf.

► When working on scaffolding, the operator must be secured with a safety belt as the magnetic drilling machine (magnetic drill press) can oscillate dangerously in the event of an interruption to the power supply.

► Check for secure clamping of the electromagnets on the substrate before every use.

► Secure the magnetic drilling machine (magnetic drill press) with the safety chain supplied when working in an inclined or vertical position and during overhead work. The magnetic drilling machine (magnetic drill press) could fall down if the magnet is loosened or the power fails.

► Check that the tool is tightened securely before using.

► Do not allow the connecting cable to hang over edges (trip effect).

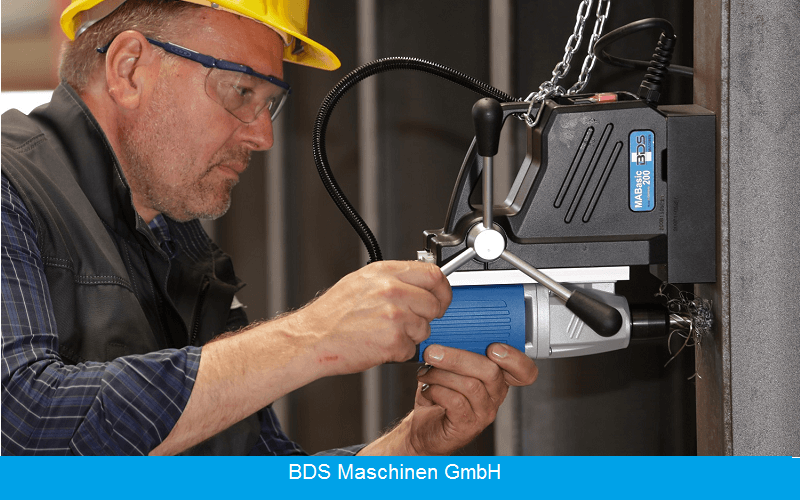

I. Working in Inclined or Vertical Position (Drilling Horizontally or Overhead):

When working in inclined or vertical position and during overhead work, the magnetic drilling machine (magnetic drill press) must be secured to prevent it from falling using the safety chain supplied.

► Check the safety chain for proper function before every use. A damaged safety chain must not be used. Replace a damaged safety chain immediately.

► Attach the safety chain in such a way that the magnetic drilling machine (magnetic drill press) moves away from the operator in the event of slipping.

► Lay the safety chain as tightly as possible around the handle of the magnetic drilling machine (magnetic drill press).

► Check the secure fitting of the safety chain and lock before starting work.

► Use the protective equipment.

J. Check The Condition Of The Substrate (material to be drilled):

J. Check The Condition Of The Substrate (material to be drilled):

The magnetic clamping force is dependent on the condition of the substrate. The clamping force is significantly reduced by paint, zinc and scale coatings and rust. The substrate must satisfy the following conditions in order to achieve sufficient magnetic clamping force:

■ The substrate must be magnetic.

■ The clamping surface and the magnetic foot must be clean and grease-free.

■ The clamping surface must be completely smooth and level.

► Clean the substrate and the magnetic foot of the magnetic drilling machine (magnetic drill press) before use.

► Remove any unevenness and loose rust from the substrate.

The best clamping effect is obtained on low-carbon steel substrate with a thickness of at least 20 mm.

Steel with low thickness: When drilling into low thickness steel, an additional steel plate (minimum dimensions 100 x 200 x 20 mm) must be placed under the workpiece. Secure the steel plate to prevent it from falling.

NF (non-ferrous or non-magnetic) metals or workpieces with an uneven surface: A special holding device must be used when drilling into NF metals or into workpieces with an uneven surface.

K. Cleaning The Magnetic Drill Press After Use:

After each use

■ Remove the inserted tool.

■ Remove swarf and coolant residues.

■ Clean the tool and the tool holder on the magnetic drilling machine (magnetic drill press).

■ Clean the guide of the magnetic drilling machine (magnetic drill press) slide.

■ Put the magnetic drilling machine (magnetic drill press) and accessories into the transport case.

BDS Maschinen Channel Partner In The USA: CS Unitec, Inc https://www.csunitec.com

BDS Maschinen Worldwide: https://www.bds-machines.com

If You Like This Article Please Click Here To Rate & Review Us!